Your Partner in Workplace Safety & Compliance

At Workplace Safety Management, we don’t just supply products and services — we deliver peace of mind.

Our blog is here to showcase expert insights, real-world case studies, and the latest innovations in air quality, dust and fume extraction, and LEV compliance.

Whether you manage a busy workshop, factory, or commercial site, you’ll find practical advice and proven solutions to keep your workforce safe, your operations efficient, and your business fully compliant.

Your Partner in Workplace Safety & Compliance

At Workplace Safety Management, we don’t just supply products and services — we deliver peace of mind.

Our blog is here to showcase expert insights, real-world case studies, and the latest innovations in air quality, dust and fume extraction, and LEV compliance.

Whether you manage a busy workshop, factory, or commercial site, you’ll find practical advice and proven solutions to keep your workforce safe, your operations efficient, and your business fully compliant.

Ensuring Safety, Efficiency, and Reliability with LEV Systems in Engineering

In the engineering and manufacturing sector, ensuring workplace safety is always a critical priority. One of the most significant hazards, however, is often invisible: the air that employees breathe every day. Processes such as welding, cutting, grinding, and chemical treatments generate fumes, dust, and vapors that can affect both short-term comfort and long-term health. Workers exposed to these airborne contaminants may experience respiratory issues, skin irritation, and other chronic conditions.

At the same time, dust and debris can interfere with machinery, causing maintenance issues and production delays. This makes it clear that proper ventilation is not optional. That’s why Local Exhaust Ventilation (LEV systems) for engineering workplaces are essential. They capture hazardous particles directly at the source, protecting employees, improving equipment efficiency, and maintaining a healthier, safer, and more productive work environment. By investing in the right LEV solutions, businesses can create operational stability while ensuring compliance with safety regulations.

Alt text for Image: "LEV systems in engineering workshop controlling airborne dust and fumes to protect workers."

Why LEV Systems Are Vital in Engineering

1. Control of Harmful Substances

Every engineering process has the potential to release harmful substances into the air. Welding can emit metal fumes, chemical treatments release vapours, and grinding generates fine dust. Exposure to these substances without proper extraction can lead to serious health risks, including lung inflammation, skin irritation, and chronic respiratory illnesses.

Implementing LEV systems for engineering workplaces ensures that contaminants are captured at the point of emission, preventing them from spreading throughout the workspace. This not only protects workers but also reduces the need for extensive cleaning and maintenance caused by airborne dust settling on machinery and surfaces.

2. Compliance with COSHH Regulations

The Control of Substances Hazardous to Health (COSHH guidance) regulations require businesses to minimise employee exposure to harmful substances. Non-compliance can result in legal penalties, operational interruptions, and reputational damage. LEV systems are a proven solution to meet these standards.

Regular COSHH testing and well-maintained LEV systems demonstrate a business’s commitment to employee safety. They also provide peace of mind to management and workers alike, knowing that the workplace meets or exceeds regulatory requirements.

3. Protection for Machinery and Products

Airborne particles are not just a threat to people; they also impact machinery and products. Dust accumulation can cause breakdowns in sensitive equipment such as CNC machines, precision tools, or 3D printers, while contaminants can compromise product quality.

High-quality LEV systems for engineering workplaces prevent these disruptions by maintaining cleaner air around equipment, reducing maintenance costs, and ensuring consistent product quality. Businesses benefit from fewer production delays, lower overheads, and improved operational efficiency.

Explore our full range of expert LEV systems services today. Get in touch to see how we can keep your workplace safe and compliant. ( Link to Service Page )

Key Features of Modern LEV Systems

Source Capture: Extraction hoods and arms positioned directly at points of emission, whether at welding benches, chemical baths, or cutting stations. This ensures that harmful particles are captured before they spread.

High-Efficiency Filtration: Advanced filters remove even the smallest airborne particles, ensuring only clean air is recirculated in the workspace.

Automated Controls: Sensors and smart controls adjust airflow automatically to maintain optimal performance and energy efficiency.

Custom Design: Every engineering environment is unique. Bespoke LEV systems are designed to match facility layout, processes, and compliance requirements, ensuring maximum safety and efficiency.

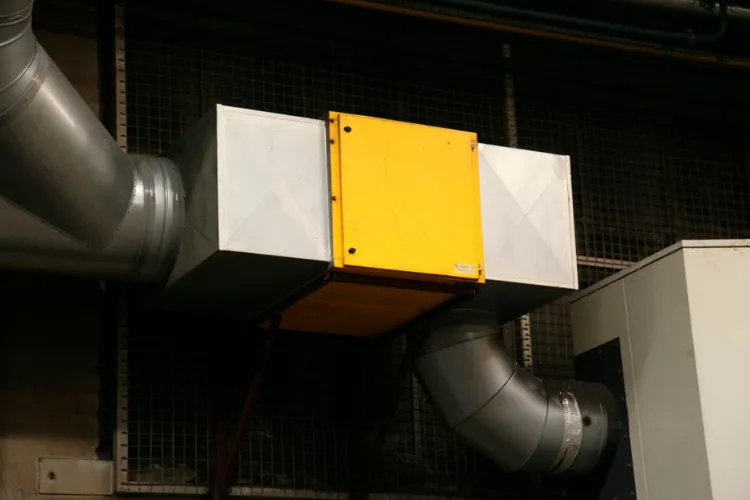

Alt text for Image: “High-efficiency LEV systems with automated controls ensuring clean air in a manufacturing environment.”

The Workplace Safety Management Approach

At Workplace Safety Management, we understand the challenges of maintaining safe engineering workplaces. Our team provides:

Full design and installation of bespoke LEV systems

Replacement and upgrades for outdated or underperforming equipment

Genuine spare parts for all leading LEV brands

Scheduled COSHH testing, maintenance, and documentation

Ongoing support to ensure systems operate at peak efficiency

By combining technical expertise with safety knowledge, we ensure your LEV systems perform optimally, protecting both employees and equipment.

Reach out to our experts today and find the perfect LEV system for your engineering workplace.

Real-World Impact of LEV Systems

Investing in high-quality LEV systems is more than just a compliance measure. It directly protects your workforce and ensures operational reliability. One of our recent engineering clients reported a significant reduction in absenteeism and equipment downtime after installing upgraded LEV systems. Cleaner air led to improved workplace morale, enhanced productivity, and measurable cost savings.

Businesses that adopt LEV systems for engineering workplaces benefit from both regulatory compliance and increased operational efficiency. Cleaner environments mean fewer health risks, less maintenance, and higher consistency in production, all of which contribute to a more profitable and sustainable business.

Alt text for Image: "Engineers inspecting LEV systems to maintain workplace safety and COSHH compliance."

Steps to Achieve a Safer Workplace with LEV Systems

Upgrading or installing LEV systems may seem daunting, but a structured approach ensures success:

Assess Current Ventilation: Identify gaps and potential hazards in your existing system.

Design a LEV Solution: Consider facility layout, machinery, and compliance requirements.

Install Modern LEV Systems: Ensure optimal placement and integration for efficiency.

Maintain and Monitor Performance: Schedule regular maintenance and COSHH checks to sustain reliability.

Following these steps ensures both employee safety and operational efficiency, creating a stable and productive workplace.

The Future of Safe Engineering Workplaces

As manufacturing processes become more advanced, airborne hazards remain a concern. Modern LEV systems are evolving too, incorporating smart sensors, real-time monitoring, and energy-efficient solutions. Companies that invest in these systems not only protect their employees but also position themselves as industry leaders in safety and compliance.

By choosing professional LEV systems for engineering workplaces, businesses demonstrate commitment to employee well-being while achieving long-term operational benefits. Cleaner air, safer workspaces, and protected machinery translate into measurable productivity gains.

Alt text for Image: "Modern LEV systems with smart sensors and real-time monitoring maintain safe air quality in an engineering workplace."

Final Thoughts

LEV systems are no longer optional; they are essential. They protect workers from hazardous substances, ensure COSHH compliance, safeguard machinery, and enhance productivity. Workplace Safety Management provides expert guidance, installation, and ongoing support to ensure that your LEV systems operate at peak efficiency.

Investing in LEV systems for engineering workplaces creates safer, healthier, and more productive environments, benefiting employees, equipment, and the overall business. Make the smart choice today to protect your most valuable assets.

Take the Next Step

Don’t let invisible hazards put your team or your business at risk. Whether you need a new LEV system, a replacement, or spare parts for ongoing maintenance, Workplace Safety Management has the expertise and resources to help.

Frequently Asked Questions (FAQs)

1. What are LEV systems, and why are they important in engineering workplaces?

LEV systems, or Local Exhaust Ventilation systems, are designed to capture hazardous fumes, dust, and vapours at the source. They protect workers from respiratory issues, prevent equipment damage, and ensure safer, cleaner, and more efficient operations.

2. How do LEV systems help maintain COSHH compliance?

LEV systems control exposure to harmful substances, which is a key requirement of COSHH compliance. Properly installed and maintained systems demonstrate a business’s commitment to regulatory standards and employee safety.

3. Can LEV systems improve machinery performance and product quality?

Yes. By removing airborne dust and particles, LEV systems reduce wear and tear on machinery and prevent contamination of products. This leads to fewer breakdowns, consistent output, and improved overall efficiency.

4. How often should LEV systems be inspected for COSHH compliance?

Regular inspection and maintenance are crucial. Businesses should schedule routine checks, filter replacements, and COSHH testing to ensure the system continues to meet regulatory standards and operates at peak efficiency.

5. What is the long-term benefit of investing in professional LEV systems for engineering workplaces?

Professional LEV systems provide long-term protection for employees and equipment, reduce operational downtime, support COSHH compliance, and increase overall productivity, creating a safer and more sustainable work environment.

Ensuring Safety, Efficiency, and Reliability with LEV Systems in Engineering

In the engineering and manufacturing sector, ensuring workplace safety is always a critical priority. One of the most significant hazards, however, is often invisible: the air that employees breathe every day. Processes such as welding, cutting, grinding, and chemical treatments generate fumes, dust, and vapors that can affect both short-term comfort and long-term health. Workers exposed to these airborne contaminants may experience respiratory issues, skin irritation, and other chronic conditions.

At the same time, dust and debris can interfere with machinery, causing maintenance issues and production delays. This makes it clear that proper ventilation is not optional. That’s why Local Exhaust Ventilation (LEV systems) for engineering workplaces are essential. They capture hazardous particles directly at the source, protecting employees, improving equipment efficiency, and maintaining a healthier, safer, and more productive work environment. By investing in the right LEV solutions, businesses can create operational stability while ensuring compliance with safety regulations.

Alt text for Image: "LEV systems in engineering workshop controlling airborne dust and fumes to protect workers."

Why LEV Systems Are Vital in Engineering

1. Control of Harmful Substances

Every engineering process has the potential to release harmful substances into the air. Welding can emit metal fumes, chemical treatments release vapours, and grinding generates fine dust. Exposure to these substances without proper extraction can lead to serious health risks, including lung inflammation, skin irritation, and chronic respiratory illnesses.

Implementing LEV systems for engineering workplaces ensures that contaminants are captured at the point of emission, preventing them from spreading throughout the workspace. This not only protects workers but also reduces the need for extensive cleaning and maintenance caused by airborne dust settling on machinery and surfaces.

2. Compliance with COSHH Regulations

The Control of Substances Hazardous to Health (COSHH guidance) regulations require businesses to minimise employee exposure to harmful substances. Non-compliance can result in legal penalties, operational interruptions, and reputational damage. LEV systems are a proven solution to meet these standards.

Regular COSHH testing and well-maintained LEV systems demonstrate a business’s commitment to employee safety. They also provide peace of mind to management and workers alike, knowing that the workplace meets or exceeds regulatory requirements.

3. Protection for Machinery and Products

Airborne particles are not just a threat to people; they also impact machinery and products. Dust accumulation can cause breakdowns in sensitive equipment such as CNC machines, precision tools, or 3D printers, while contaminants can compromise product quality.

High-quality LEV systems for engineering workplaces prevent these disruptions by maintaining cleaner air around equipment, reducing maintenance costs, and ensuring consistent product quality. Businesses benefit from fewer production delays, lower overheads, and improved operational efficiency.

Explore our full range of expert LEV systems services today. Get in touch to see how we can keep your workplace safe and compliant. ( Link to Service Page )

Key Features of Modern LEV Systems

Source Capture: Extraction hoods and arms positioned directly at points of emission, whether at welding benches, chemical baths, or cutting stations. This ensures that harmful particles are captured before they spread.

High-Efficiency Filtration: Advanced filters remove even the smallest airborne particles, ensuring only clean air is recirculated in the workspace.

Automated Controls: Sensors and smart controls adjust airflow automatically to maintain optimal performance and energy efficiency.

Custom Design: Every engineering environment is unique. Bespoke LEV systems are designed to match facility layout, processes, and compliance requirements, ensuring maximum safety and efficiency.

Alt text for Image: “High-efficiency LEV systems with automated controls ensuring clean air in a manufacturing environment.”

The Workplace Safety Management Approach

At Workplace Safety Management, we understand the challenges of maintaining safe engineering workplaces. Our team provides:

Full design and installation of bespoke LEV systems

Replacement and upgrades for outdated or underperforming equipment

Genuine spare parts for all leading LEV brands

Scheduled COSHH testing, maintenance, and documentation

Ongoing support to ensure systems operate at peak efficiency

By combining technical expertise with safety knowledge, we ensure your LEV systems perform optimally, protecting both employees and equipment.

Reach out to our experts today and find the perfect LEV system for your engineering workplace.

Real-World Impact of LEV Systems

Investing in high-quality LEV systems is more than just a compliance measure. It directly protects your workforce and ensures operational reliability. One of our recent engineering clients reported a significant reduction in absenteeism and equipment downtime after installing upgraded LEV systems. Cleaner air led to improved workplace morale, enhanced productivity, and measurable cost savings.

Businesses that adopt LEV systems for engineering workplaces benefit from both regulatory compliance and increased operational efficiency. Cleaner environments mean fewer health risks, less maintenance, and higher consistency in production, all of which contribute to a more profitable and sustainable business.

Alt text for Image: "Engineers inspecting LEV systems to maintain workplace safety and COSHH compliance."

Steps to Achieve a Safer Workplace with LEV Systems

Upgrading or installing LEV systems may seem daunting, but a structured approach ensures success:

Assess Current Ventilation: Identify gaps and potential hazards in your existing system.

Design a LEV Solution: Consider facility layout, machinery, and compliance requirements.

Install Modern LEV Systems: Ensure optimal placement and integration for efficiency.

Maintain and Monitor Performance: Schedule regular maintenance and COSHH checks to sustain reliability.

Following these steps ensures both employee safety and operational efficiency, creating a stable and productive workplace.

The Future of Safe Engineering Workplaces

As manufacturing processes become more advanced, airborne hazards remain a concern. Modern LEV systems are evolving too, incorporating smart sensors, real-time monitoring, and energy-efficient solutions. Companies that invest in these systems not only protect their employees but also position themselves as industry leaders in safety and compliance.

By choosing professional LEV systems for engineering workplaces, businesses demonstrate commitment to employee well-being while achieving long-term operational benefits. Cleaner air, safer workspaces, and protected machinery translate into measurable productivity gains.

Alt text for Image: "Modern LEV systems with smart sensors and real-time monitoring maintain safe air quality in an engineering workplace."

Final Thoughts

LEV systems are no longer optional; they are essential. They protect workers from hazardous substances, ensure COSHH compliance, safeguard machinery, and enhance productivity. Workplace Safety Management provides expert guidance, installation, and ongoing support to ensure that your LEV systems operate at peak efficiency.

Investing in LEV systems for engineering workplaces creates safer, healthier, and more productive environments, benefiting employees, equipment, and the overall business. Make the smart choice today to protect your most valuable assets.

Take the Next Step

Don’t let invisible hazards put your team or your business at risk. Whether you need a new LEV system, a replacement, or spare parts for ongoing maintenance, Workplace Safety Management has the expertise and resources to help.

Frequently Asked Questions (FAQs)

1. What are LEV systems, and why are they important in engineering workplaces?

LEV systems, or Local Exhaust Ventilation systems, are designed to capture hazardous fumes, dust, and vapours at the source. They protect workers from respiratory issues, prevent equipment damage, and ensure safer, cleaner, and more efficient operations.

2. How do LEV systems help maintain COSHH compliance?

LEV systems control exposure to harmful substances, which is a key requirement of COSHH compliance. Properly installed and maintained systems demonstrate a business’s commitment to regulatory standards and employee safety.

3. Can LEV systems improve machinery performance and product quality?

Yes. By removing airborne dust and particles, LEV systems reduce wear and tear on machinery and prevent contamination of products. This leads to fewer breakdowns, consistent output, and improved overall efficiency.

4. How often should LEV systems be inspected for COSHH compliance?

Regular inspection and maintenance are crucial. Businesses should schedule routine checks, filter replacements, and COSHH testing to ensure the system continues to meet regulatory standards and operates at peak efficiency.

5. What is the long-term benefit of investing in professional LEV systems for engineering workplaces?

Professional LEV systems provide long-term protection for employees and equipment, reduce operational downtime, support COSHH compliance, and increase overall productivity, creating a safer and more sustainable work environment.

Talk to our Team today about your ventilation requirements

Talk to our Team today about your ventilation requirements

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

Workplace Safety Management Ltd

Unit 1 Garden Court

Gee Road

Coalville

Leicestershire

LE67 4NB

Email: [email protected]

COMPANY INFO

CUSTOMER INFO

2025 Workplace Safety Management & Products