Skip to Main Content | 310-970-0007 | [email protected]

Skip to Main Content | 310-970-0007 | [email protected]

What is SIPP?

Discover SIPP (Spray-In-Place-Pipe): The Next Generation of Pipe Rehabilitation

SIPP, or Spray-In-Place-Pipe, is the key to unlocking the repair potential in even the smallest pipe sizes, all the way down to 1 ¼”.

Internal pipe coating is a great option for pipe rehabilitation for pipes without significant cracks or breaks.

Let’s explore what SIPP is, how it functions, and why it’s an advanced solution for contemporary pipe repairs.

How Does SIPP Work?

The SIPP process involves several key steps:

1. Inspection and Preparation

Before coating the pipe, it is important to properly prepare the surface. This usually involves cleaning the pipe with a mechanical tool such as chain knockers and brushes ran by a flexible shaft to remove any debris or contaminants, and possibly roughing up the surface to provide a better bonding surface for the coating.

2. Application of Spray Coating

The coating material is applied using a centrifugal-force rotated spray head, which sprays a thin layer of the material onto the inside surface of the pipe.

The material may be applied in one or more layers, depending on the thickness of the coating desired. Usually, 3 application layers is recommended.

The epoxy resin can also be applied with a spray gun that can be attached to Spraypoxy's MidiCoater System.

3. Curing

After the coating material has been applied, it must be allowed to cure.

This typically involves letting the material sit for a period of time, during which it will harden and become fully bonded to the surface of the pipe.

The Spraypoxy Blower 3200 W can be used to accelerate the process.

4. Inspection

Once the coating has fully cured, the pipe should be inspected with an inspection camera to ensure that it has been applied properly and that there are no defects or areas of thin coverage.

This may involve visual inspection and/or testing using specialized equipment.

If everything meets quality standards, the pipe is ready to return to service.

What Are the Benefits of SIPP Rehabilitation?

Fixes Even the Most Challenging Pipes

When other pipe repair techniques come out short, Spraypoxy will help you repair even the most challenging pipes.

Cost-Effective

The low cost of materials and reduced labor costs due to short working time help you and your customers save money.

Extremely Easy to Use

Spraypoxy machines are easy to use and there's no need to open wall and floor structures when repairing the pipeline.

Quick to Move Around and Apply

Spraypoxy equipment is mobile and light weight - this allows you to work in a quicker and more efficient manner.

Environmentally Friendly

When using Spraypoxy pipe coating products, pipe repairs can be conducted without producing any dust or hazardous waste.

Ready to go Trenchless?

Fill out this form and we'll get in touch to answer any questions and help you select the right trenchless solutions for your plumbing needs.

Our SIPP Supplies

MidiCoater+

The MidiCoater integrates two machines in one for cleaning and spraying functionality. Its integrated electric motor can be used to operate flexible shafts to clean or brush coat pipes.

You can also coat the pipes with Spraypoxy's proprietary spray coating technology by installing a high-speed, centrifugal-force driven spray head for applying the coating.

RotoMidi and RotoMax

These high-tech milling machine's from Boldan are designed to efficiently clean pipes, removing roots, concrete, failed gaskets, and other pipe imperfections. Engineered with safety and efficiency in mind, they can work with a comprehensive range of tools suitable for sewer renovation.

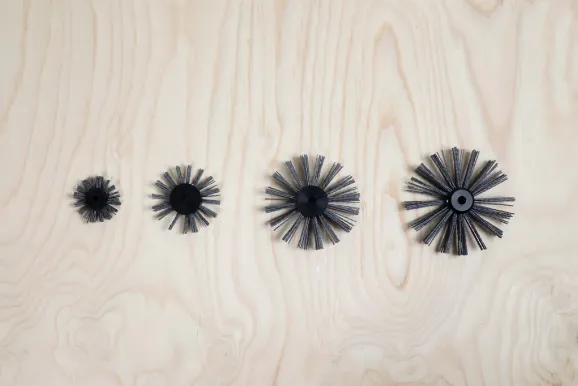

Cleaning Brushes

Carbide cleaning brush for removing fine dust or light mineral deposits in PVC and fragile pipes. Also used for brush coating pipe preparation.

Nylon cleaning brushes for the Mini and Midi Cleaners. Custom designed, high-quality and long-lasting brush use for coating and cleaning PVC pipes.

Ready to learn more?

Send us your information using the form below and we'll reach out to answer any questions you may have and help you select the best trenchless supplies for your needs.

536 HAJOCA CORP COMPTON

1220 W WALNUT STREET

COMPTON, CA 90220-5010

Master Distributor of Trenchless Supplies

310-970-0007

© Copyright 2024 Hajoca Corporation | All Rights Reserved | Privacy Policy | Accessibility Statement