Coredeq Services

We offer four distinct services: Prototypes, Volume Manufacturing, Molding Tools Export, and PCB Assembly. Our ordering process is swift, taking under 2 minutes. You can expect to receive your quote conveniently in your email within 24 hours.

Because It’s Time for Prototypes

CNC Machining, 3D Printing Services, Vacuum Casting and Sheet Metal Fabrication, Are all methods for extremely Rapid manufacturing of Prototypes and Mockups

Coredeq presents an extensive range of manufacturing techniques to fulfill your distinct needs and preferences. For instance, our CNC machining services cater to both small and large production runs, accommodating projects of any intricacy and material choice. With our user-friendly Instant Quoting Engine, receive a quote within 24 hours, guiding you to the optimal manufacturing approach. Subsequently, we expedite the creation of your accurate metal or plastic components, delivering them to your doorstep in as few as 10 days.

01

CNC Machining

Our 5-axis mills, grinders, and lathes ensure no geometry is too intricate, guaranteeing comprehensive manufacturing capabilities.

02

3D Printing

Also known as Additive Manufacturing. Our

high experience in different methods (FDM, SLS, SLA) and materials means that almost everything is possible.

03

Vacuum Casting

This adaptable technique emulates Injection Molding, crafting intricate polyurethane parts without costly metal tools.

04

Sheet Metal Fabrication

For achieving the intended form, processes encompass cutting, bending, punching, and welding, guaranteeing meticulous precision and accuracy.

Because It’s Time for Volume Manufacturing

01

Injection Molding

The process for producing parts by injecting molten material into a mold. Mainly including polymers and elastomers (Plastics and Rubber).

02

Metal Injection Molding

Finely-powdered metal is mixed with binder material to create a "feedstock" that is then shaped and solidified using injection molding.

03

Die Casting

Is a process used to produce metal parts by injecting molten metal into a mould. The economical way of producing large quantities of complex, high- tolerance parts in metal.

04

Metal Stamping

Is a cold-forming process that makes use of dies (tools) and stamping presses to transform sheet metal into your chosen shape or design.

Injection Molding, Die Casting and Stamping are the methods to secure your High-Volume Production. All forms of Plastics including Elastomers (Rubber and Silicone) as well as Metals in a wide variety of Alloys (Aluminum, Stainless Steel and Zinc/Zamak) are offered.

At Coredeq, we also offer a full variety of high-volume manufacturing methods. We provide you a tooling offer together with a Tooling-DfM (Design for Manufacturing), securing that your parts are well suited for Volume Manufacturing. Our user-friendly Quoting Engine provides you with a quote within 24h, guiding you to the most suitable manufacturing method.

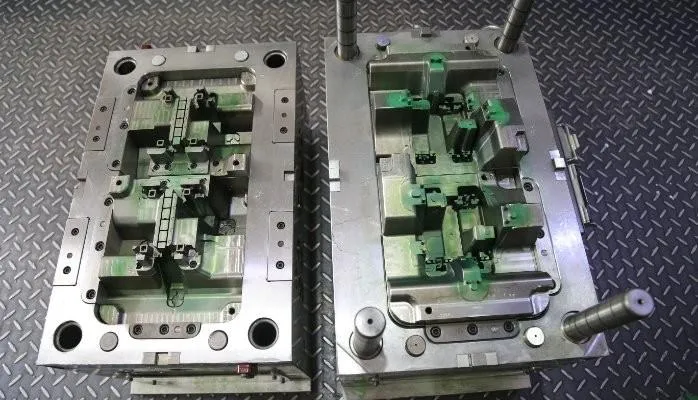

Because It’s Time for Injection Molding Tools Export

Explore your ultimate hub for mold making supplies for mass production right here at Coredeq. Renowned and empowered by our trusted partners, we specialize in delivering all-encompassing solutions that perfectly align with your needs.

Count on us to provide cost-effective production molds and top-tier exported molds, perfectly tailored to meet the requirements of your projects. In addition to our comprehensive mold-making services, Coredeq ensures that your tools are customized precisely to your specifications. We adhere to the European standard, commonly known as the Hasco standard, to guarantee the utmost quality and compatibility with your requirements. We ensure efficient processes with:

Tool Making: Usually 5 to 7 weeks, prioritizing precision and timeliness, contingent on part size and complexity.

Shipping: Effortlessly delivering to global ports in approximately 30 days, including Europe and beyond. Your seamless journey with us begins

01

Your design or ours

We can create and deliver export molds based on your existing design or assist in designing one tailored to your product and injection molding equipment. To proceed, we'll need your injection machine details. You'll receive a 3D tooling design for approval before production begins.

02

Wide range of molding tools

After approved Tool-DFM (Design For Manufacturability) the mold will be designed and built normally according to the HASCO (European) standard. It will be optimized for production on your injection molding machine with details on hot runner system and cooling line connections already prepared for your existing setup. Pilot and short production runs are available upon mold completion, such as for bridging a production tooling gap.

03

Fast Turnaround

Our large facility and machining capabilities allow us to build molds quickly, whatever the application or material, which means you can get your moldings completed faster. Our customers will have chances to view the mold(s) via live video or recorded video. Test run will be performed in our factory and samples will be submitted to customers for approval.

04

Cost-Efficient Shipping Solutions

Shipping a 20ft container to Europe ranges from $1500 to $3000 USD. We offer door-to-door service for 5800 kgs or 1.3 cubic meters to Central Europe at a flat rate of $2500 USD, ensuring cost-effective and convenient shipping.

Because It’s Time for Printed Circut Board Assembly (PCBA)

01

SMT Assembly

SMT Assembly: Surface-mounted components placed directly onto PCBs for efficient electronic manufacturing.

02

Through-Hole Assembly

Through-Hole Assembly: Components with leads inserted into drilled PCB holes for robust connections in electronics.

03

BGA Assembly

BGA Assembly: Ball Grid Array – advanced tech for compact, high-performance chip connections on PCBs.

04

And more..

Mixed Assembly, Rigid Flex PCB, Various Assembly Services, Electro Mechanical, Box Build Assembly, Product Assembly, Cable Assemblies and more.

We provide an array of assembly services including SMT Assembly, BGA Assembly, Through-Hole Assembly, Mixed Assembly, Rigid Flex PCB Assembly Services, Electro Mechanical Assembly, Box Build Assembly, Product Assembly, and Cable Assemblies.

Coredq specializes in manufacturing and distributing premium high-density double-sided and multilayer PCBs. We provide comprehensive PCB Assembly and Electronic Manufacturing Services, catering to both sample and large-scale production needs. Our commitment to rapid delivery and exceptional client service extends globally. We maintain stringent adherence to diverse standards, including IPC 610 Class 2 and Class 3, ensuring unparalleled compliance and quality.

© 2025 Coredeq AB - All Rights Reserved

Kruthornsgränden 9, 226 52 Lund, Sweden